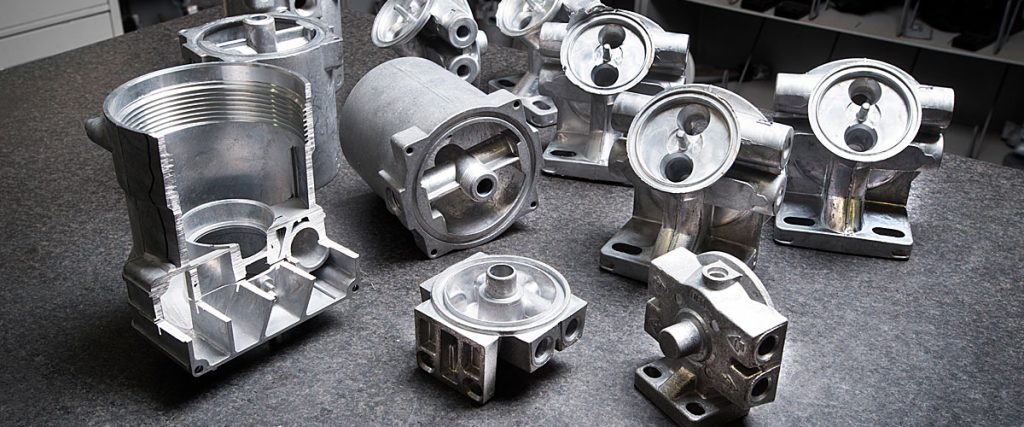

At Sadiq Global Metallurgy Services, we specialize in providing expert consultancy for aluminium casting processes—offering clients the technical knowledge, strategic guidance, and hands-on support needed to achieve world-class casting operations.

Our Expertise

We combine industry experience with advanced metallurgical insights to guide businesses in setting up, optimizing, and scaling their aluminium casting facilities. Whether you are planning a new plant, improving product quality, or reducing production costs, our consultants ensure your operations are efficient, sustainable, and competitive.

Our Aluminium Casting Consultancy Includes:

1. Process Design & Optimization

- Guidance on selecting the right casting method (sand casting, die casting, investment casting, permanent mold, etc.)

- Process flow development for maximum efficiency

- Optimizing cycle times, cooling rates, and solidification for quality improvement

2. Equipment Selection & Setup

- Recommendations for furnaces, molds, dies, and automation tools

- Layout planning for smooth production flow

- Assistance with installation and commissioning

3. Alloy Selection & Metallurgy Support

- Advice on the best aluminium alloys for your product requirements

- Custom alloy development for strength, corrosion resistance, and lightweight applications

- Troubleshooting metallurgical defects

4. Quality Control & Defect Reduction

- Training teams on modern inspection methods (X-ray, ultrasonic, dye penetrant testing, etc.)

- Root cause analysis of defects such as porosity, shrinkage, inclusions, or cracks

- Developing best practices to ensure consistent product quality

5. Sustainability & Cost Efficiency

- Energy-saving practices in melting and casting operations

- Recycling and re-melting solutions for aluminium scrap

- Reducing waste, rejections, and overall production costs

6. Training & Skill Development

- On-site and virtual training sessions for engineers, operators, and managers

- Practical workshops on defect identification and corrective actions

- Knowledge transfer to ensure long-term self-sufficiency

7. Ongoing Technical Support

- Remote and on-site troubleshooting

- Continuous improvement strategies

- Regular audits and performance evaluations

Why Choose Us?

- Industry Expertise: Decades of experience in aluminium metallurgy and casting.

- Customized Solutions: Tailored consultancy for your exact industry and product needs.

- End-to-End Guidance: From concept and design to production and quality control.

- Global Standards: Ensuring your processes meet international benchmarks.

Sadiq Global Metallurgy Services helps you transform challenges into opportunities by making your aluminium casting operations more efficient, profitable, and sustainable.

No responses yet